Petrified Wood Indonesia is a direct Indonesian petrified wood manufacturer and wholesale export supplier serving global B2B buyers. Operated by CV. Karya Bersama and based in Bogor, Indonesia, we specialize in container-scale production of petrified wood dining tables, coffee tables, sinks, tiles, and custom fossil stone décor.

We are not a trading intermediary.

We are the production source.

With documented annual shipments reaching hundreds of thousands of kilograms, large-format industrial cutting capability, and direct control over licensed mining networks across Indonesia, we operate as a vertically integrated petrified wood furniture factory built for wholesale distribution and project manufacturing.

We supply:

• Container-based distributors

• Interior project contractors

• Hospitality developers

• Luxury furniture brands

• International stone importers

Our structure is built for scale, customization, and export reliability.

Manufacturing Infrastructure and Industrial Capacity

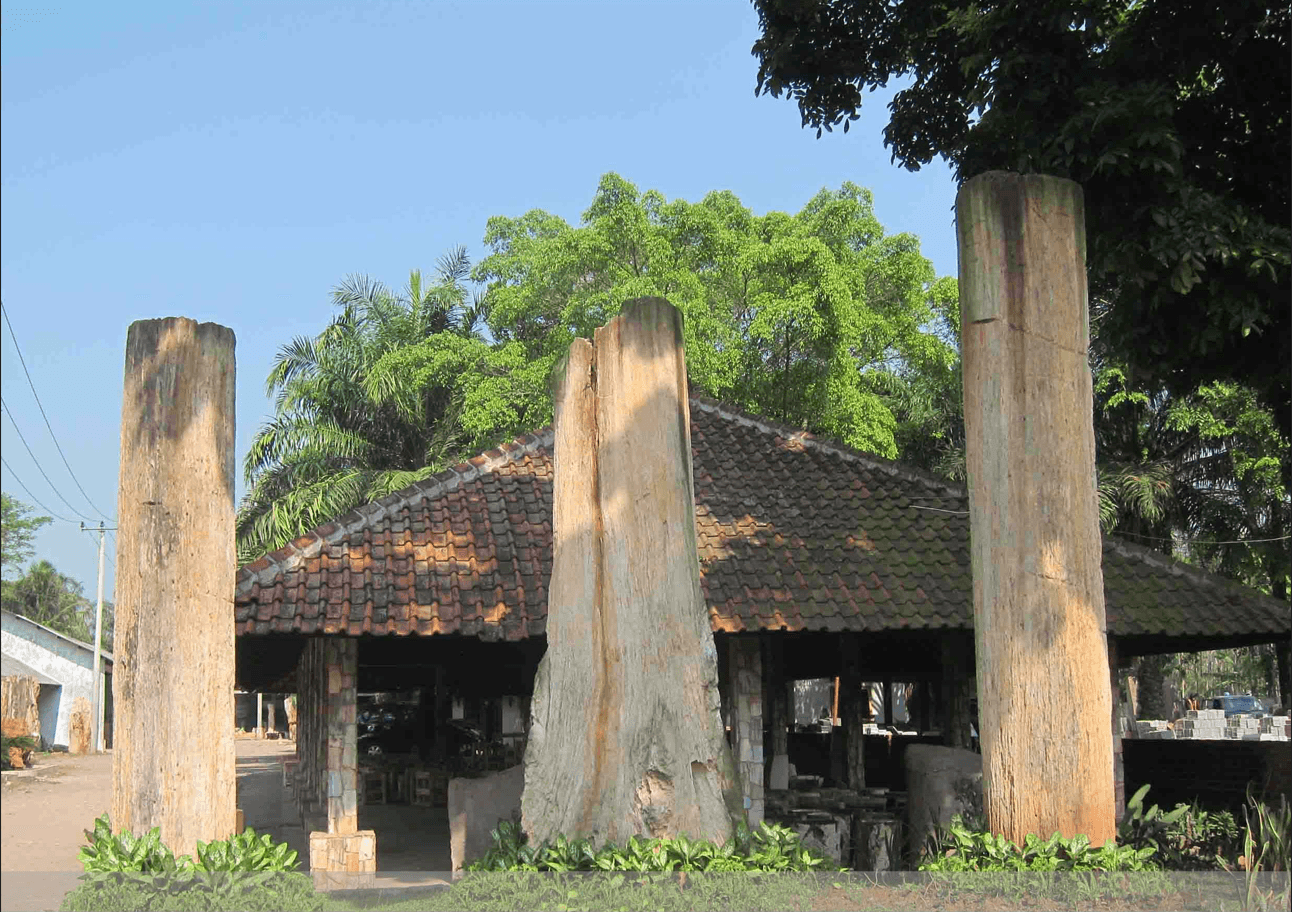

Petrified Wood Indonesia operates as a dedicated Indonesian petrified wood manufacturer with full in-house production control. Our facility is based in Bogor and functions as a centralized petrified wood furniture factory serving global B2B buyers.

Unlike fragmented workshops that rely on outsourced cutting and finishing, our production infrastructure is vertically organized. Raw slabs, cutting, shaping, stabilization, finishing, inspection, and packaging are coordinated under one operational system.

Our workforce consists of approximately 134 team members, including craftsmen, cutting technicians, finishing specialists, logistics coordinators, administrative officers, and export handlers. This structure allows us to manage both standardized wholesale production and custom project-based manufacturing.

We operate multiple cutting machines designed for different production scales:

• One large-format cutting unit capable of processing slabs for dining tables up to approximately five meters in length

• Three mid-scale machines dedicated to dining tables and large coffee tables

• Multiple smaller cutting units optimized for stools, sinks, tiles, and decorative objects

This tiered machine structure enables us to manage both oversized statement pieces and high-volume smaller units simultaneously without production bottlenecks.

For tile production and dimension-sensitive orders, we utilize CNC processing to ensure uniform thickness and installation precision. For dining tables and artistic coffee tables, manual finishing remains essential to preserve the natural grain, fossil structure, and character of the material.

Our manufacturing flexibility is built for two buyer categories:

- Container-based distributors requiring consistent volume

- Interior project contractors requiring custom dimensions and aesthetic control

Documented Production Scale (2019–2025)

Industrial credibility must be supported by measurable output.

Below is our documented production history:

• 2019: 20,508 pieces, 1,208,581 kilograms shipped

• 2020: 15,045 pieces, 569,997 kilograms shipped

• 2021: 34,908 pieces, 1,111,750 kilograms shipped

• 2022: 27,379 pieces, 944,083 kilograms shipped

• 2023: 42,857 pieces, 981,259 kilograms shipped

• 2024: 35,304 pieces, 1,135,010 kilograms shipped

• 2025: 29,409 pieces, 794,357 kilograms shipped

These numbers represent actual exported units across dining tables, coffee tables, sinks, tiles, and decorative objects of varying sizes.

On average, we ship three to four 40-foot containers per month, depending on customization complexity and order volume. A 40-foot container typically carries between 15 to 18 tons, while a 20-foot container averages 8 to 11 tons.

This documented output positions us as a high-volume petrified wood supplier Indonesia buyers rely on for stable supply.

Factory Workflow: From Raw Fossil to Finished Product

Our production workflow follows a structured sequence designed to reduce defect risk and maintain consistency:

- Raw slab selection and grading

Each slab is evaluated for density, color tone, and crack tolerance. - Primary cutting

Slabs are cut according to buyer specification using appropriate machine scale. - Structural assessment

Large-format tables are evaluated for reinforcement requirements. When necessary, internal steel support structures are installed to maintain long-term stability. - Crack stabilization

Depending on aesthetic preference, natural cracks may be preserved, stabilized using resin, or structurally reinforced. - Surface finishing

Tiles undergo CNC finishing for dimensional consistency. Dining tables and artistic pieces receive manual finishing to preserve organic character. - Drying process

Depending on client requirements, slabs may be kiln dried or air dried before finishing. - Quality inspection

Measurements, surface finish, and structural integrity are verified. - Packaging preparation

Units are prepared for protective crate packing.

This controlled workflow differentiates us from trading intermediaries who outsource production to multiple small workshops without standardized process control.

Direct Raw Material Sourcing and Geological Authority

As an Indonesian petrified wood manufacturer, our supply chain begins at licensed mining sources across Banten, Sumatra, Jambi, and other fossil-rich regions.

We do not depend on fluctuating third-party supply chains.

Direct sourcing allows us to:

• Maintain consistent quality grading

• Secure rare color variants

• Control material density selection

• Plan production schedules more reliably

Our internal grading system evaluates petrified wood based on:

Color

Dark tones are rarer and often command higher wholesale value. Natural bright tones are more abundant but vary in fossil pattern density.

Density

Higher-density material is preferred for structural pieces such as dining tables.

Crack tolerance

Natural fossilization creates cracks. We classify slabs based on structural impact and aesthetic suitability.

Buyers may choose between:

• Natural aesthetic with visible fossil cracks

• Resin-stabilized finish for smoother appearance

• Reinforced structure for oversized installations

This flexibility supports both rustic luxury aesthetics and modern architectural applications.

Large-Format Manufacturing Capability

One of our distinguishing strengths as a petrified wood furniture factory is the ability to produce oversized dining tables beyond typical workshop limitations.

Our primary large-format cutting machine allows processing of slabs suitable for tables up to approximately five meters.

Large tables are structurally assessed before final finishing. If structural integrity requires reinforcement, we install internal steel structures to maintain long-term durability.

This capability makes us suitable for:

• Luxury resort installations

• High-end hospitality projects

• Statement residential commissions

• Large commercial spaces

Smaller workshops often lack both machine capacity and structural engineering considerations required for oversized fossil wood tables.

Why Manufacturing Depth Matters for Wholesale Buyers

For container-based distributors and project contractors, manufacturing depth reduces supply risk.

Working directly with an Indonesian petrified wood manufacturer provides:

• Predictable lead times

• Consistent grading

• Volume scalability

• Custom dimension flexibility

• Direct communication with production team

This is structurally different from purchasing through resellers who may not control production schedules.

As a wholesale petrified wood supplier, our strength lies not in retail presentation, but in operational control from raw fossil to container loading.

Export Logistics and Container Optimization

As a wholesale petrified wood supplier operating at container scale, logistics discipline is as critical as manufacturing quality.

Our primary export port is Jakarta, Tanjung Priok, Indonesia’s largest international shipping hub. From this port, we ship regularly to the United States, Japan, Australia, Europe, the United Kingdom, Canada, Dubai, and Singapore.

We support both FOB and CIF terms depending on buyer preference. For clients with established freight forwarders, FOB Jakarta provides cost control and flexibility. For buyers who prefer simplified handling, CIF arrangements can be coordinated.

Average container weight profile:

20-foot container

Approximately 8 to 11 tons, depending on product mix.

40-foot container

Approximately 15 to 18 tons.

Because petrified wood is dense and heavy, container loading strategy must balance weight distribution carefully. Our team plans container layout based on product dimensions and density to avoid overloading and ensure safe sea transit.

We also consolidate mixed-product containers. Distributors frequently combine dining tables, coffee tables, sinks, tiles, and smaller décor pieces within one shipment. This allows better SKU diversity while maintaining freight efficiency.

Protective Packaging and Damage Prevention

Petrified wood is stone, but it is also fossilized organic material. While extremely durable under load, it must be protected from impact during transit.

Our packaging system includes:

• Individual wooden crate reinforcement

• Custom Styrofoam interior protection

• Internal bracing to prevent lateral movement

• Edge and corner cushioning

• Moisture control measures when required

For high-value dining tables and custom designs, crate construction is adjusted based on slab thickness and weight distribution.

Before container sealing, our team documents the entire loading process through photos and video. This documentation provides transparency and helps resolve any shipping claims efficiently.

Insurance coverage is typically arranged for container shipments unless the buyer opts out.

In case of manufacturing-related breakage, we provide compensation or replacement in accordance with contract terms. If damage results from external mishandling beyond our control, we assist clients with documentation for insurance claims.

Risk management is part of wholesale responsibility.

Minimum Order Structure and Entry Flexibility

We support both emerging distributors and established container buyers.

Sample Orders

Small units can be shipped via DHL or air freight. This allows buyers to evaluate finishing quality and fossil pattern before committing to bulk production.

For sample orders, payment methods such as PayPal and Wise are accepted.

Recommended Wholesale Entry Level

USD 5,000 minimum total order value. This threshold allows buyers to build a meaningful product mix while maintaining efficient production scheduling.

Container Orders

20-foot or 40-foot FCL shipments are recommended for established distributors.

Payment Structure

For bulk orders, 50 percent deposit via T/T is required before production begins. Remaining balance is settled prior to shipment.

Lead Time Structure

Stock items

Typically 2 to 4 weeks.

Custom samples

2 to 3 weeks depending on design complexity.

Full container production

1 to 2 months depending on size range and customization level.

Clear payment and lead time policies reduce uncertainty for wholesale buyers.

Quality Inspection and Pre-Shipment Transparency

Every order undergoes structured inspection prior to shipment.

We provide:

• Measurement verification

• Surface finishing confirmation

• Stabilization verification when resin is applied

• Photo documentation

• Video documentation during container loading

Clients are welcome to appoint third-party inspection agencies at our facility.

This transparency reduces friction in long-term B2B relationships and builds confidence among new importers sourcing from Indonesia.

Wholesale Positioning: Manufacturer vs Trading Company

Many companies marketing Indonesian petrified wood operate as intermediaries.

As a petrified wood furniture factory, we differ in several structural ways:

Raw Material Control

We source directly from licensed mining areas.

Production Capacity

We operate multiple cutting machines, including large-format capability.

Volume Scalability

We handle container-based production regularly.

Customization

Private label and custom dimension capability are integrated within our production workflow.

Cost Structure

Direct manufacturing reduces layered margin from resellers.

For container-based distributors, working directly with an Indonesian petrified wood manufacturer improves pricing predictability and supply consistency.

For interior project contractors, direct production access allows dimension adjustments and project coordination without intermediary delays.

Pricing Logic Without Publishing Sensitive Numbers

While wholesale pricing varies by size, density, color rarity, and customization level, buyers benefit from direct factory negotiation rather than retail markups.

Dark-toned fossil slabs often command higher value due to rarity. Large-format dining tables require additional structural assessment and machine capacity. Tiles and standardized sinks allow more predictable per-unit pricing.

Because we control raw material sourcing and processing internally, pricing stability is higher than fragmented workshop sourcing.

For serious wholesale buyers, pricing discussions are handled directly with our export team after specification clarity.

Risk Mitigation and Long-Term Partnership Approach

In B2B stone trade, risk perception often determines supplier choice more than price alone.

We mitigate risk through:

• Documented production history

• Structured lead times

• Transparent inspection process

• Video-recorded container sealing

• Replacement or compensation policy when applicable

• Support in insurance claims documentation

This structured approach is designed for long-term distributor relationships rather than one-time transactions.

Wholesale Buyer FAQ – Direct Answers for Importers and Distributors

1. Are you a trading company or a direct Indonesian petrified wood manufacturer?

We are a direct manufacturer. Petrified Wood Indonesia operates production facilities in Bogor and sources raw material through licensed mining networks in multiple Indonesian regions. We control cutting, finishing, inspection, and export coordination internally.

2. What is the minimum order quantity for wholesale buyers?

For meaningful wholesale production, we recommend either:

• USD 5,000 minimum total order value

or

• 20-foot container load

However, we welcome smaller sample orders for evaluation purposes. Small items may be shipped via DHL or air freight before committing to full container orders.

3. How long does production take for container orders?

Lead time depends on product complexity.

Stock items typically ship within 2 to 4 weeks.

Custom samples require approximately 2 to 3 weeks.

Full container production generally requires 1 to 2 months depending on size range and customization.

We provide production updates during the process.

4. Can I mix different products in one container?

Yes.

Many distributors combine dining tables, coffee tables, sinks, tiles, and decorative objects within one shipment. Mixed container consolidation helps buyers diversify inventory while maintaining freight efficiency.

5. Do you offer private label manufacturing?

Yes.

We regularly produce under private label arrangements for distributors and retail brands. Custom branding and tailored packaging solutions, including custom styrofoam design and crate labeling, are available.

6. How do you prevent damage during international shipping?

Our packaging system includes wooden crates, internal bracing, styrofoam protection, and container weight balancing. Each shipment is documented with photo and video during loading and container sealing.

Insurance coverage is typically arranged unless declined by the buyer.

7. What happens if products arrive damaged?

If damage is due to manufacturing fault, we provide compensation or replacement according to contract terms. If damage results from external handling during transit, we assist with insurance documentation.

8. Do you provide inspection before shipment?

Yes.

We conduct internal inspection and provide measurement confirmation, surface verification, and packaging documentation. Buyers may appoint third-party inspection agencies at our facility before shipment.

9. What makes your factory different from smaller workshops?

We operate multiple cutting machines including large-format capability for oversized dining tables. Our production volume, documented shipment history, and structured export workflow allow us to handle container-scale orders consistently.

Smaller workshops may produce individual pieces, but may not manage consistent container-based export schedules.

10. Why buy directly from a petrified wood supplier Indonesia instead of a reseller?

Working directly with a manufacturer provides:

• Better pricing control

• Production transparency

• Direct communication with production team

• Greater flexibility for customization

• More stable long-term supply

For B2B buyers focused on margin stability and volume reliability, direct factory relationships reduce layered intermediary costs.

Strategic Buyer Positioning

Container-based distributors often provide the most stable recurring volume. Interior project contractors and hospitality developers typically require high-value custom pieces with unique dimensions.

As an Indonesian petrified wood manufacturer, we support both segments:

Distributors gain scalable production and mixed container consolidation.

Project contractors gain dimension flexibility and structural assessment support for oversized installations.

Our infrastructure is built for wholesale trade, not retail walk-in sales.

Final Conversion Section

For serious wholesale buyers seeking:

• A direct petrified wood furniture factory

• Stable container-scale production

• Custom dimension capability

• Licensed raw material sourcing

• Structured export workflow

Petrified Wood Indonesia offers manufacturing depth and documented export experience.

We encourage qualified importers, distributors, and project contractors to contact our export team to discuss:

• Wholesale catalogue

• Production capacity

• Sample arrangements

• Container scheduling

• Private label options

Petrified Wood Indonesia

Operated by CV. Karya Bersama

Bogor, Indonesia

Email: [email protected]

WhatsApp: +62 822-3327-7919